In terms of application, the fully threaded rod 1/4 finds utility across various sectors

Applications in the Textile Industry

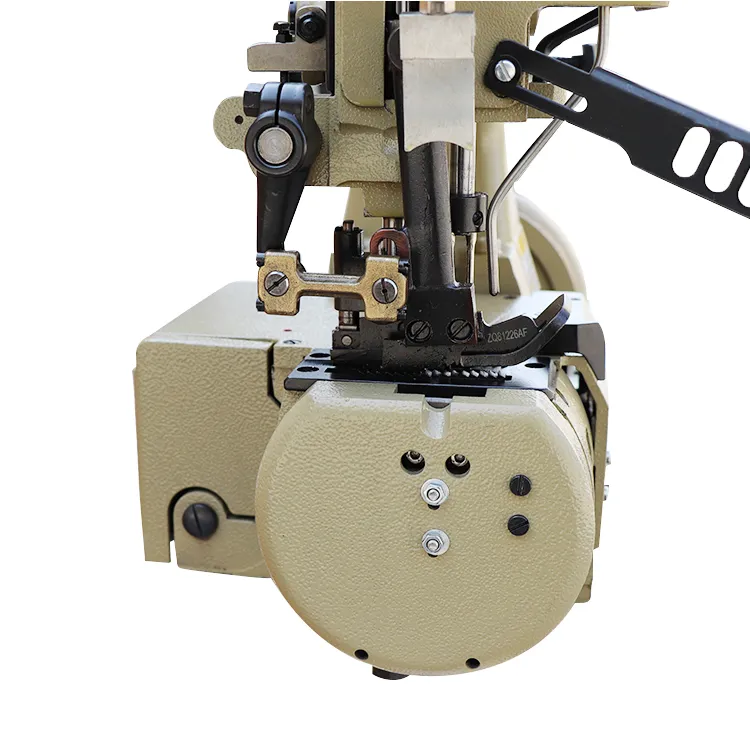

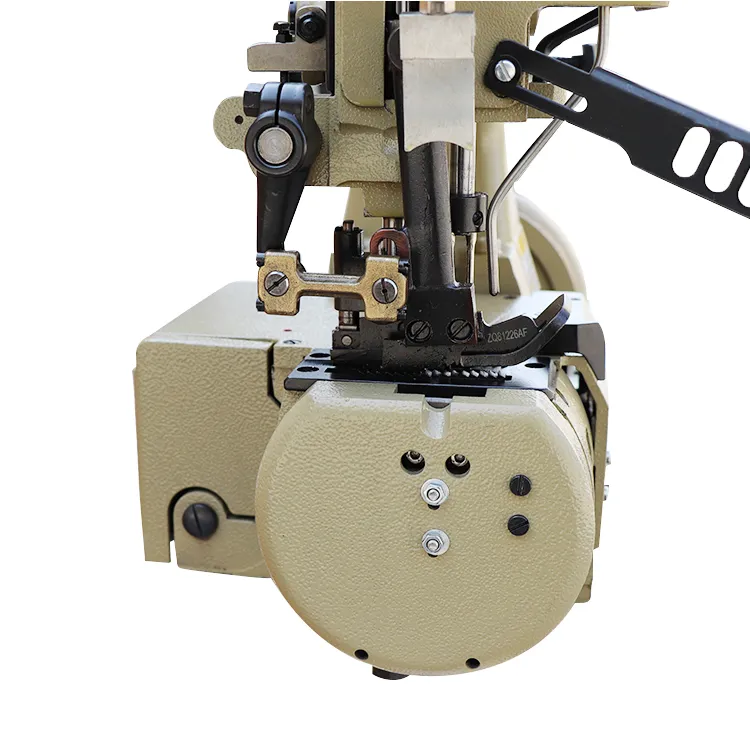

Portable bag closer machines are designed to close bags of various materials, including poly, paper, and woven bags. These machines are particularly useful in industries such as agriculture, food processing, and construction, where bags are essential for containing products like grains, fertilizers, and pet food. The ability to quickly seal bags at different locations helps streamline operations and reduce labor costs.

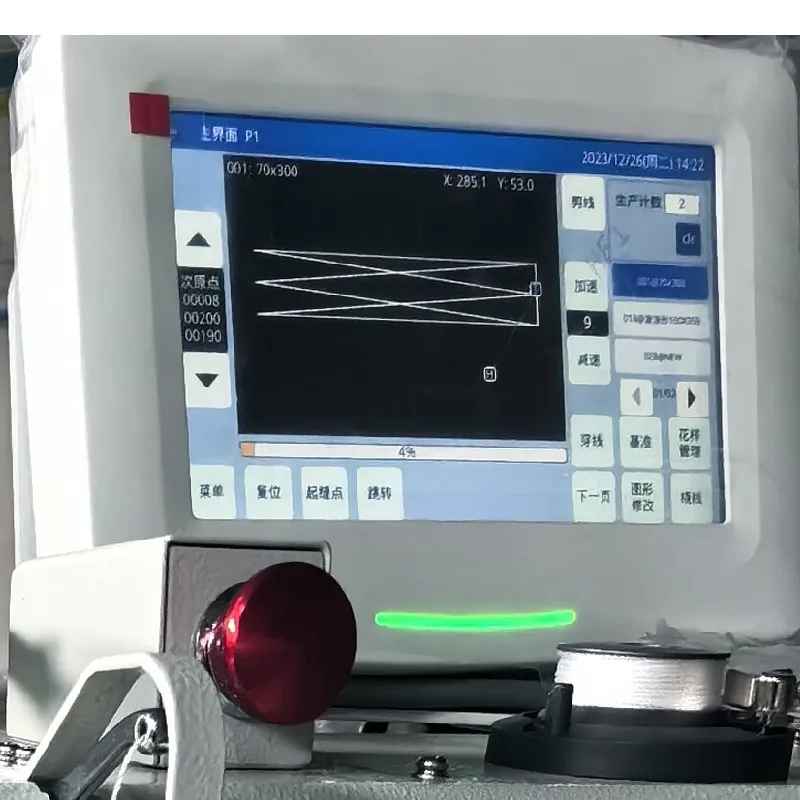

1. Automation and Efficiency

Additionally, zigzag stitches are often used for creating buttonholes. Many machines even come with automatic buttonhole features, which make sewing buttonholes a breeze, especially when working on clothing or accessories. The stretch capabilities of the zigzag stitch also make it perfect for sewing knits, as the stitch allows the fabric to stretch without breaking, ensuring comfort and flexibility.

Conclusion

- In addition to their efficiency and versatility, saddle stitch machines also produce a professional-looking finished product

In conclusion, upholstery stitching machines are vital in the evolution of the upholstery industry. They combine speed, accuracy, and versatility with the ability to cater to diverse needs, making them indispensable to manufacturers in furniture and automotive sectors. As technology continues to advance, the role of these machines will only expand, allowing for greater creativity, sustainability, and efficiency in upholstery production. Thus, investing in the right upholstery stitching machine is an investment in a company’s ability to meet modern consumer demands while maintaining high-quality standards.

Stitching Techniques

- Overall, the choice between a serger and an overlock machine will depend on your specific sewing needs and budget. If you primarily work with knits and want a machine that can create professional finishes on seams and edges, a serger may be the better option. However, if you are looking for a versatile machine that can handle a wide range of sewing tasks, an overlock machine may be more suitable.

Machine Speed Control

Conclusion

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly refurbished heavy duty sewing machine. By choosing a refurbished machine, you are helping to reduce waste and extend the life of a high-quality product.

refurbished heavy duty sewing machine. By choosing a refurbished machine, you are helping to reduce waste and extend the life of a high-quality product.As industries increasingly seek reliable and sustainable packaging options, the importance of PP woven bag stitching machines continues to rise. These machines not only streamline the production process but also ensure that the end product is both functional and environmentally friendly. Investing in advanced stitching technology can ultimately be a game-changer for manufacturers, positioning them at the forefront of the shifting packaging landscape. The integration of efficiency, cost reduction, and sustainability makes the PP woven bag stitching machine an invaluable asset in modern manufacturing practices.

1. Strength and Security Lock stitches are strong and secure, making them ideal for seams that need to withstand tension, such as those found in denim jeans or heavy-duty outdoor gear.

what is lock stitch machine

Moreover, with the rise of eco-friendly sewing practices and sustainable fashions, many makers are turning to upcycling and fabric repurposing projects. The walking foot assists in sewing multiple fabric types together seamlessly, allowing for creativity without compromising on quality.

Mechanism and Operation

They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads

They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads They are made with high-quality materials and components that ensure long-lasting performance, even under heavy workloads